Automated schedule optimisation for CHP plants

Our forecast-based plant scheduling makes it possible to achieve best prices for electricity production and at the same time comply with the heat supply obligation. With flex.ENERGY, dezera offers software and hardware solutions in a service model to optimise the operation of CHP plants and thus the economic efficiency of heating networks. By using algorithms from the field of artificial intelligence, heat demand can be reliably predicted. On this basis, optimisation algorithms find the best schedules for all plants of every site. Data on the current operation and marketing revenues

can be evaluated via our customer portal.

- Avoiding negative or low electricity prices

- Increasing revenues from electricity marketing through optimised use of heat storage facilities

- Minimised risk of high payments for balancing energy

- Integrated fault and maintenance management

- Full control over economic and technical parameters of operational management

Learn more!

Operation optimization with artificial intelligence

To provide optimal plant schedules, we use a combination of artificial neural networks and optimization algorithms. Individual parameters of all plants at a site are taken into account. Among other things, efficiencies, outputs as well as minimum running times and gas prices are set individually for each heat generator. Storage levels and capacities are also included in the optimization calculation, so that all degrees of freedom and restrictions of plant operation are taken into account. On the basis of local weather forecasts, our algorithms generate heat demand forecasts that enable forward planning and proactive storage management.

Opportunities in short-term power trading

By shifting electricity production to high-price phases, trading revenues are increased. If prices drop or get negative, the heat production of CHP plants is replaced by gas boilers if necessary. Our software maps the merit order of your heat generation plants according to the parameters you set and automatically creates optimal plant schedules. Our multi-stage optimisation of plant operation enables you to market on different spotmarkets. We transmit trading schedules automatically to your existing market access. This way, the entire process from data acquisition at the plant to schedule reporting can be automated.

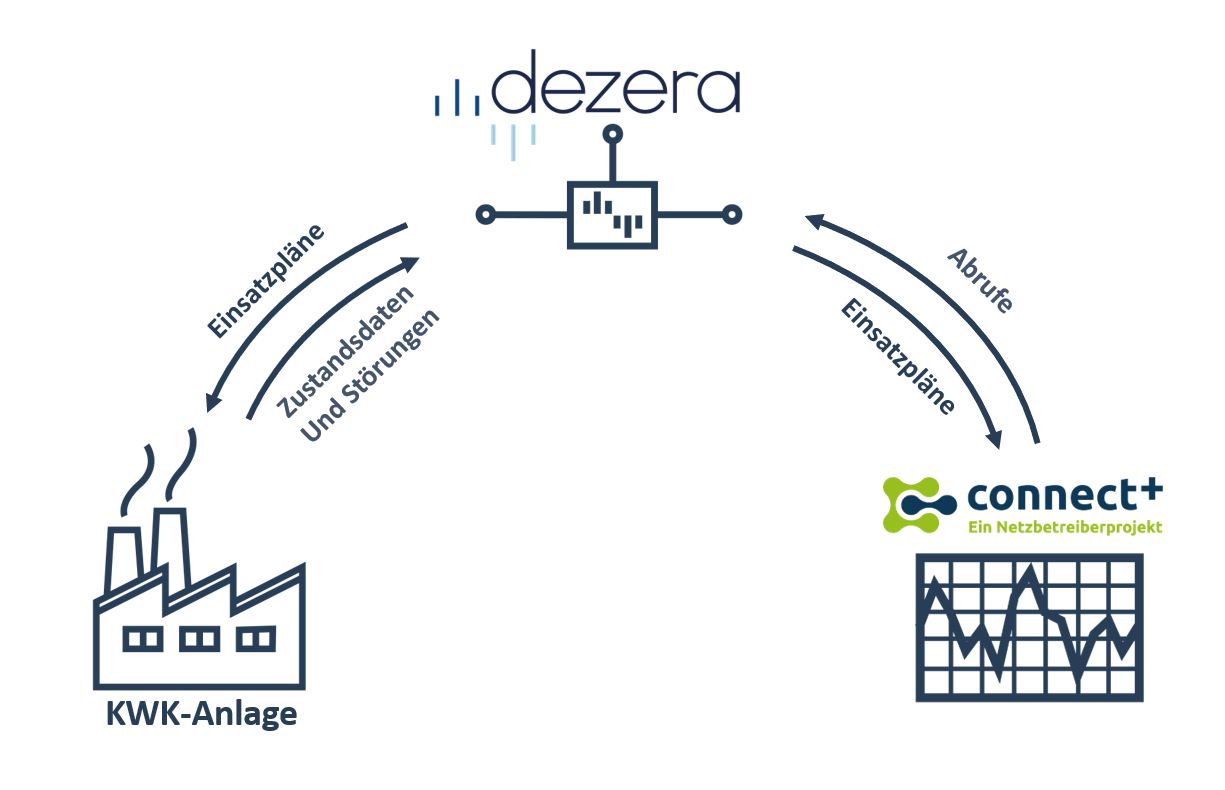

Redispatch 2.0

Our software easily implements the Redispatch 2.0 requirements for operators of CHP plants. In doing so, we take over the reporting obligations of the dispatch manager. Plant master data and deployment schedules are communicated to the responsible grid operator via the connect+ platform. In the event of a request, the plants can be controlled directly by us. In addition, the reporting obligations for plant failures and maintenance work are fulfilled automatically. In this way, you retain control over your plants despite intervention by the grid operator and can also benefit from increased revenues in electricity trading thanks to our deployment optimization.

Software-as-a-Service

dezera is a software developer and service provider. We offer software as well as hardware to make your plants responsive. Through our flexible Software-as-a-Service model, we can offer individually tailored and custom-fit solutions. Depending on which systems are in use at the customer, we offer a suitable solution for integration. Based on a dezeraBox (fieldbus integration) or as a dezeraCluster in the cloud (control system integration), we can use a variety of common interfaces for data exchange. In addition, you can view operating data, KPIs, schedules and forecasts at any time via our customer portal, as well as adjust the parameterization for your plants.